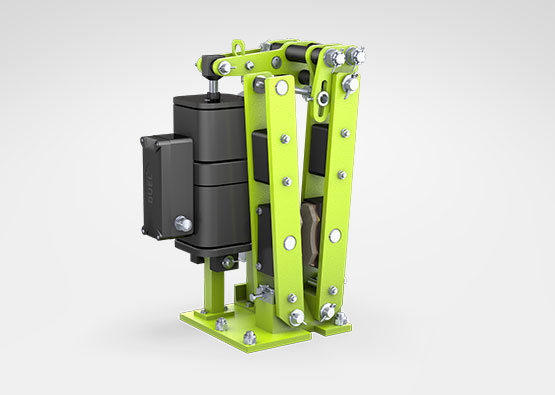

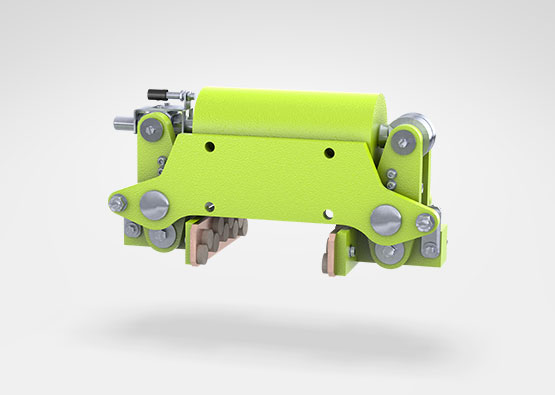

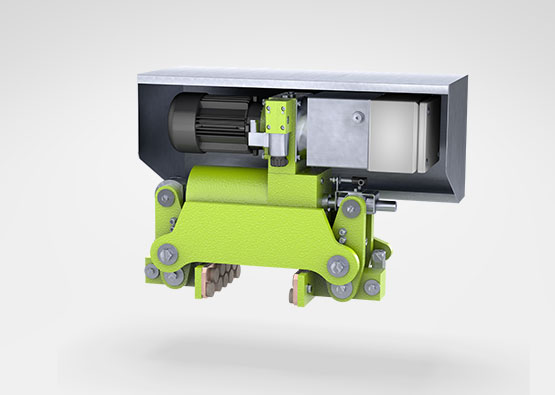

SB 8 Series

- Torque:

- Up to 20500 Nm

- Contact Force:

- Up to 45760 N

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

- Compact dimensions

- Ideal for belt conveyors in combination with long stroke thrusters

- Sintered linings for high friction speeds

- Organic, non-asbestos linings for low friction speeds

- Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube

- Stainless steel pins and spindles

- Maintenance-free bushings in all hinge points

- Right or left-hand design

- Automatic wear compensator

- Limit switch release control

- Proximity switch hand release

- Manual release lever with or without lock

- Monitoring systems (e.g. VSR/CMB)

- Brake discs with hubs or couplings

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

DELLNER BUBENZER's Anti Sway Systems allow the damping of head-block, spreader and container oscillation generated by acceleration / deceleration of trolley and gantry.

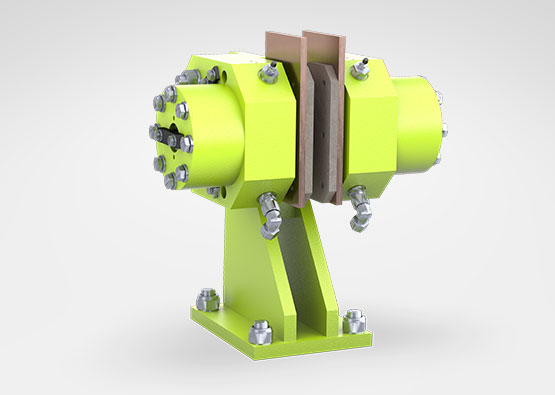

The BAC-brakes is used for stopping and/or holding of fans, blowers, wind turbines, coilers, crane slewing and travel gears etc.

Band Brake for large torque applications that can be used for emergencies or back up braking needs. Band Brakes have been around for many years and we offer many ways to operate via thruster, air, hydraulic or hand wheel.

The BOSS® Brake Only Snag System system has been developed based on the experience with the SOS system that has been already installed in more than 200 container cranes world wide.

The BCMS-4 is a micro-controller-based monitoring and switching device for spring applied brakes of the SFB and KFB series.

The Brake Control Unit BCU 2001 records characteristic current and voltage variations, which are induced by movements of the armature disk in the magnetic field of the brake coil.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane. They are hydraulic powered with HPU or BUEL® G.

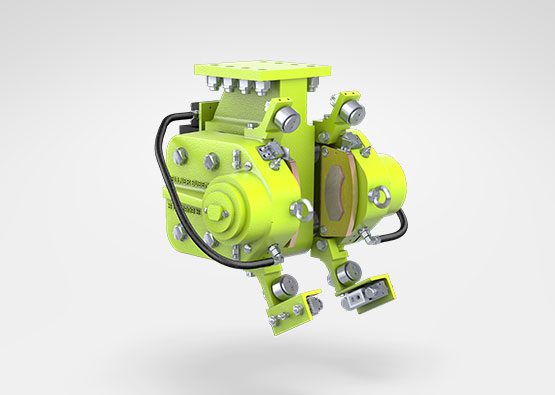

The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors.

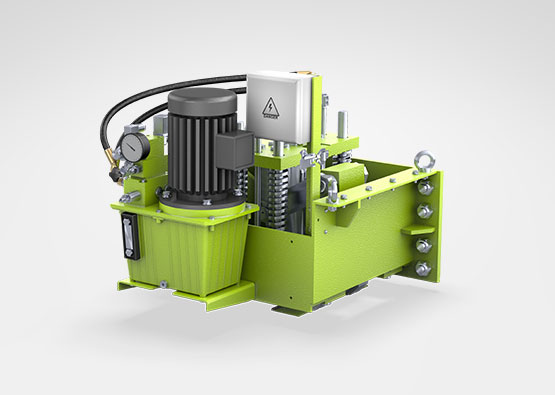

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

Compact status monitoring system for a brake system with display and fieldbus interface.

Compact status monitoring system for a brake system with display and fieldbus interface.

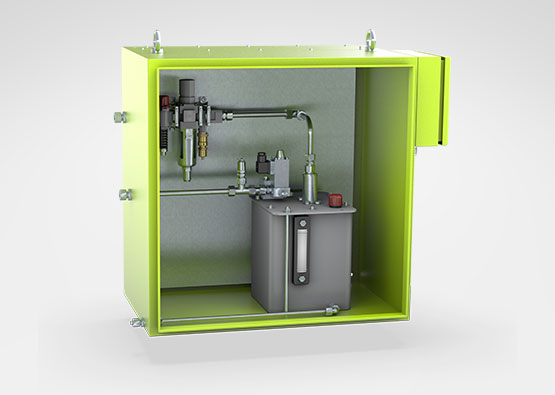

Compactus is a pneumatically operated hydraulic pump system that multiplies pneumatic line pressure into hydraulic pressure that is sufficient to operate pressure applied disc brakes at rated capacity.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

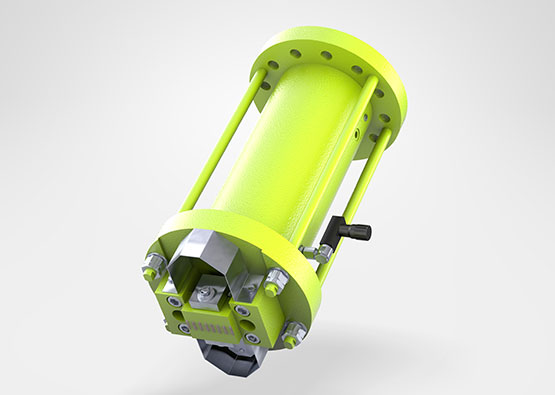

DELLNER BUBENZER's DBSB is a storm safety brake for all rail mounted equipment, e. g. cranes, stackers, reclaimers etc.

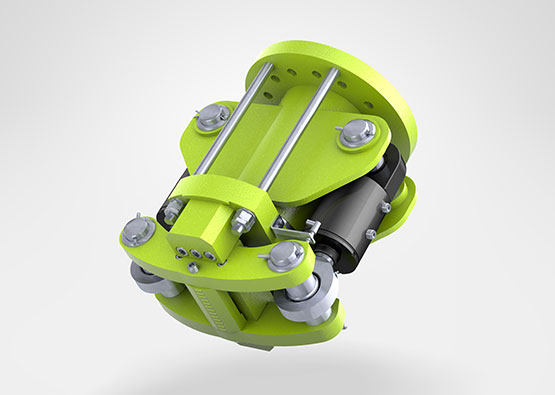

Rail brakes work pressing down on the top of rail by disk springs. Brakes are hydraulically released. Usual parking utilisation requires a few closing / opening cycles per day.

These rail clamps are storm brakes static suitable for small to medium forces. They are spring actuated; the spring exercise the closing force while an hydraulic cylinder fed by a suitable hydraulic unit provides the opening.