Braking Systems that Perform in the Harshest Conditions

Hot, dusty conditions place tough demands on the drive systems and brakes used in steelmaking. Hot metal, semi-automated rolling mills and overhead loading cranes require the most reliable, maintenance-friendly braking systems possible. DELLNER BUBENZER’s engineers and designers apply years of experience to identify the problem areas and provide high-preformance, custom braking solutions for the iron & steel industry.

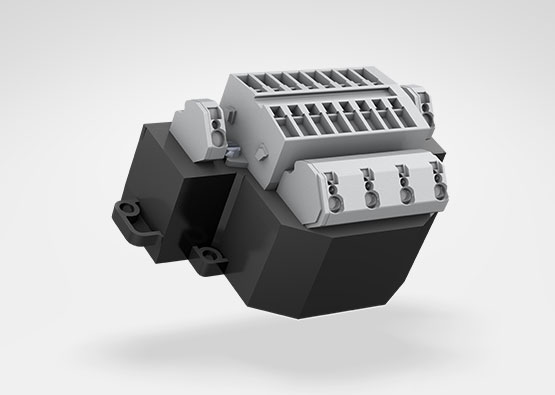

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

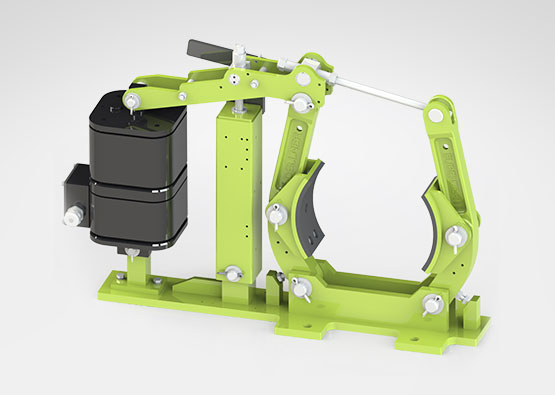

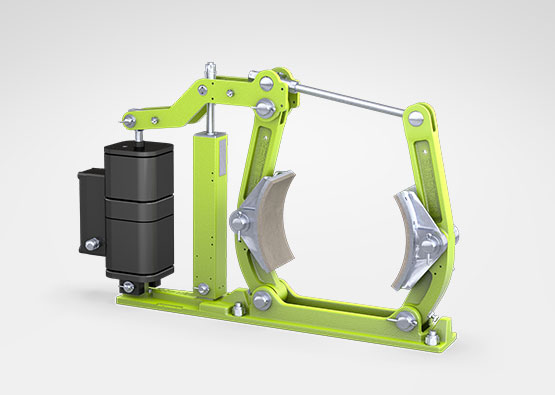

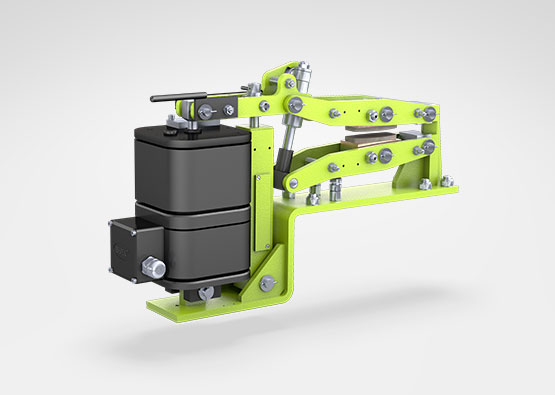

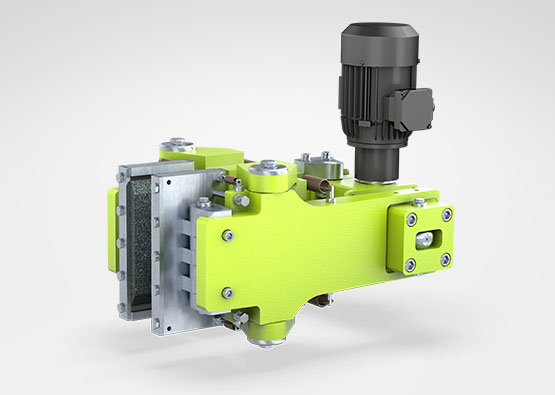

The EBA is a powerful drum brake with braking torques from 24 (ft-lb) to 9000 (ft-lb) that meets AISE (TR11) & NEMA (ICS 8) standards.

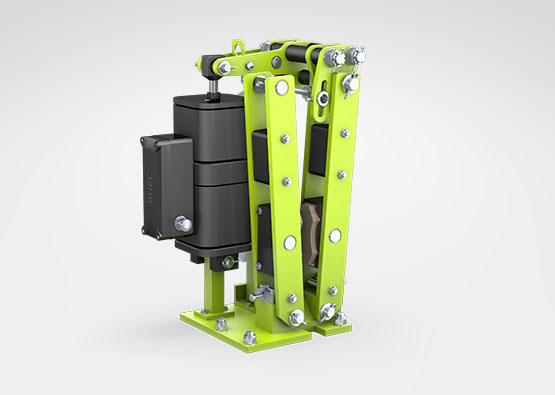

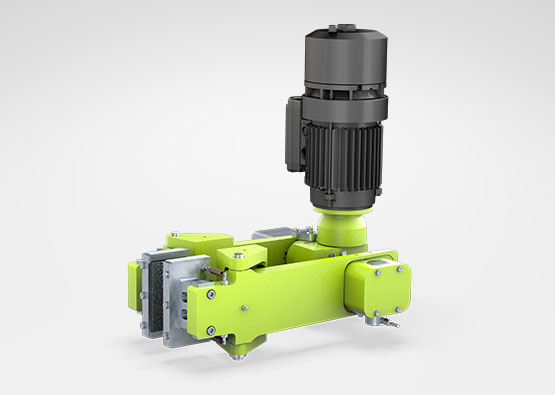

The EBH series is designed according to DIN 15435. This design is very compact and can be used in tight motor gearbox combinations.

The EBN series is designed according to DIN 15435 and has been in use in various industries for decades. EBN-2St modification: the drum brakes solution for Bridges and Sluice Systems

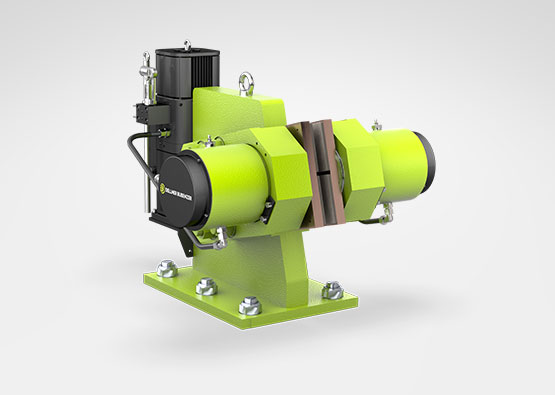

The FKT is well suited for applications with the most demanding equipment where severe clutching and braking is required.

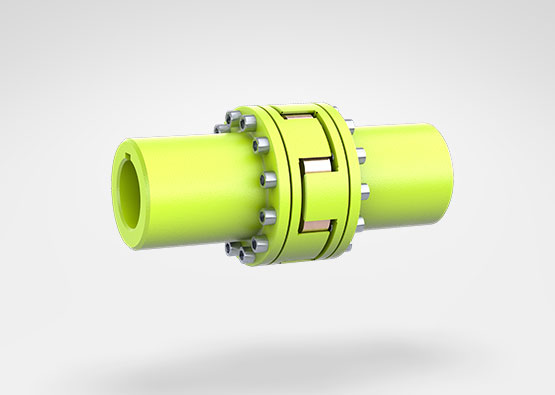

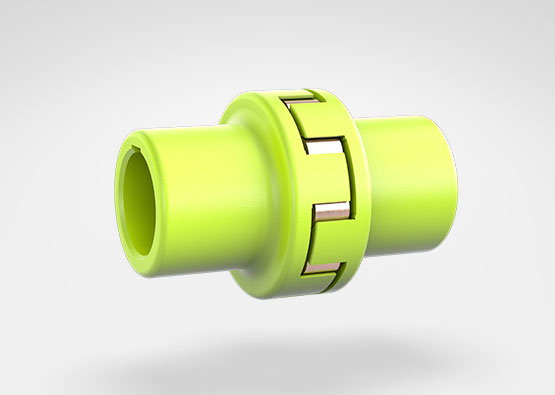

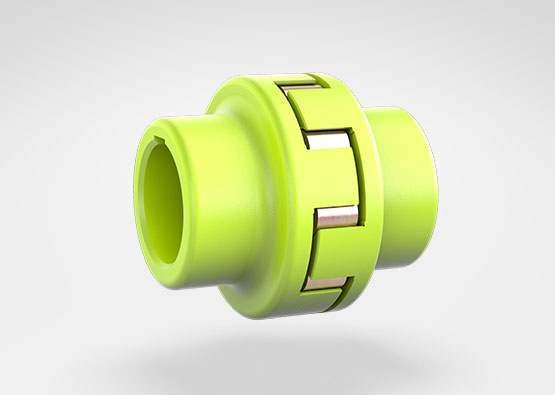

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

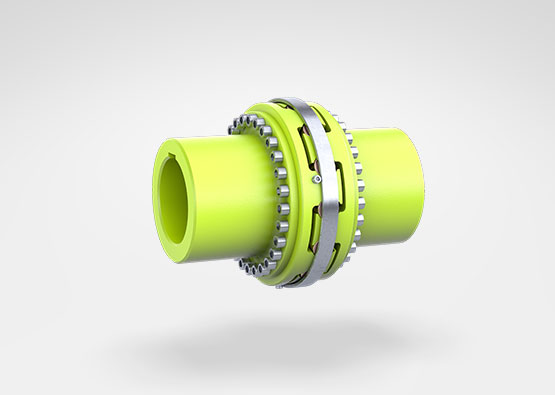

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

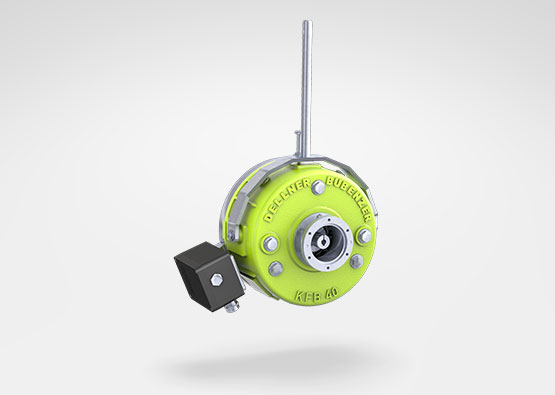

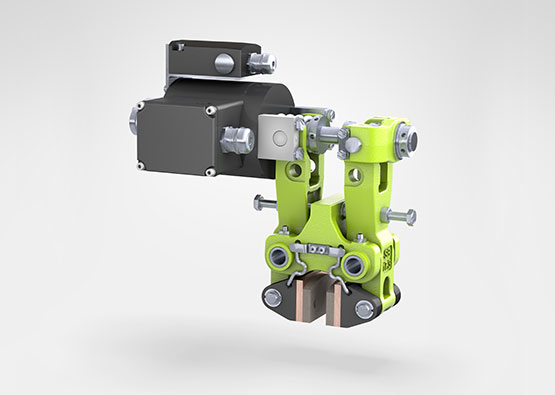

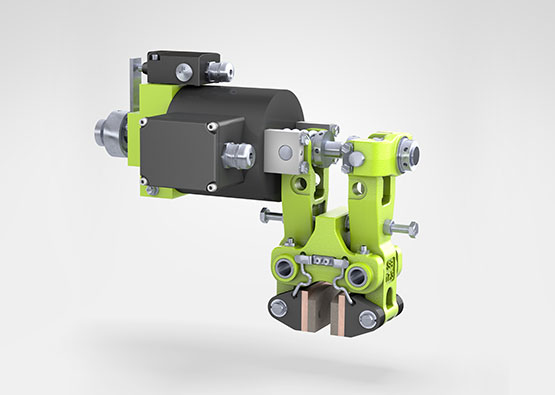

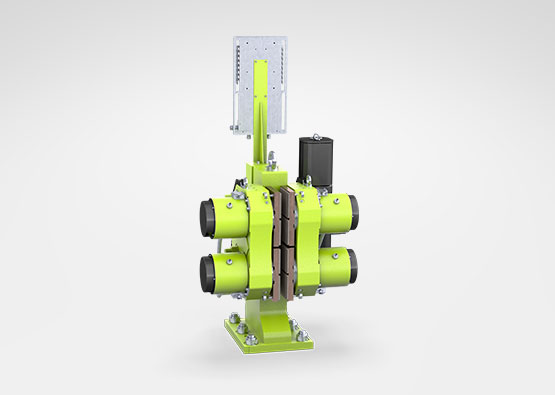

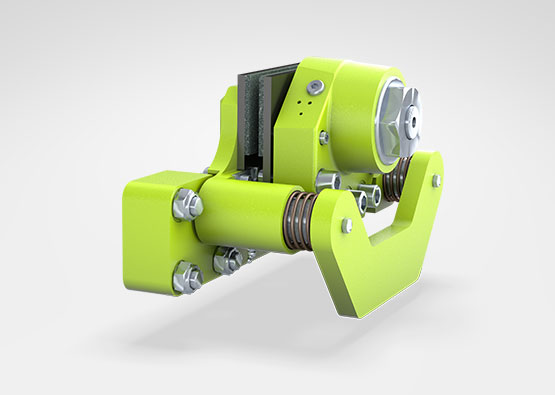

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

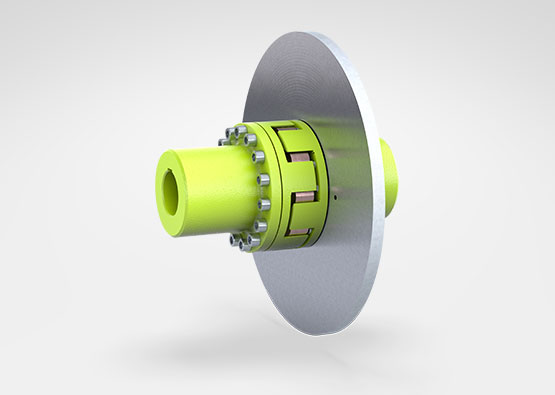

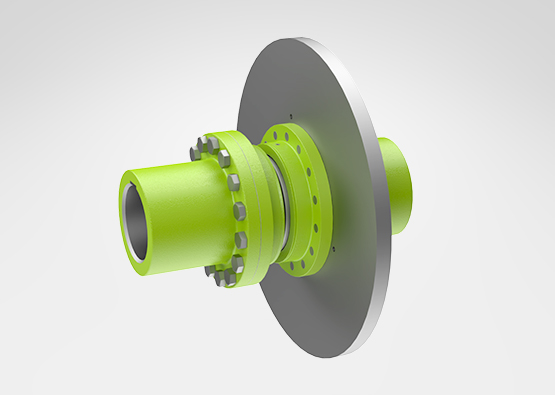

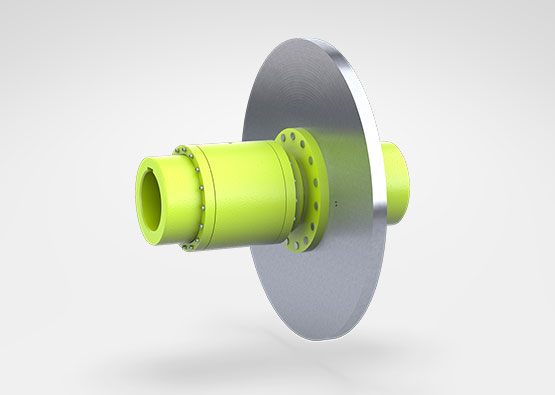

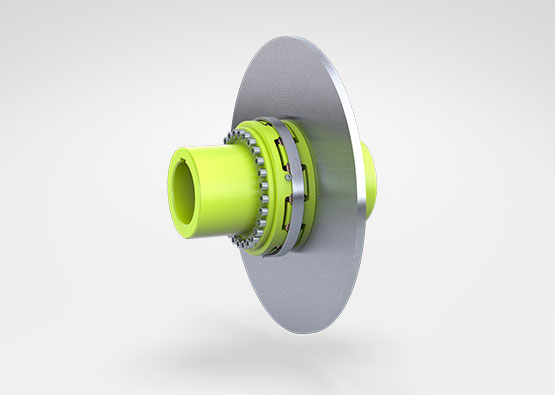

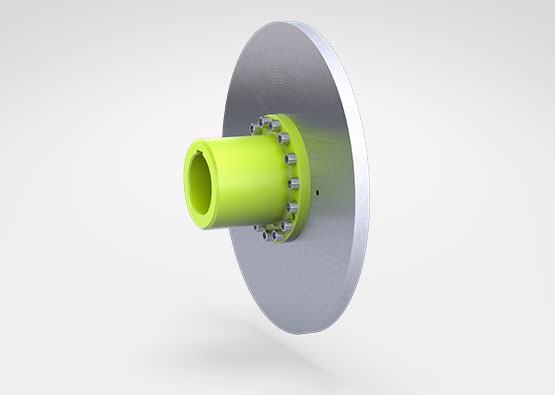

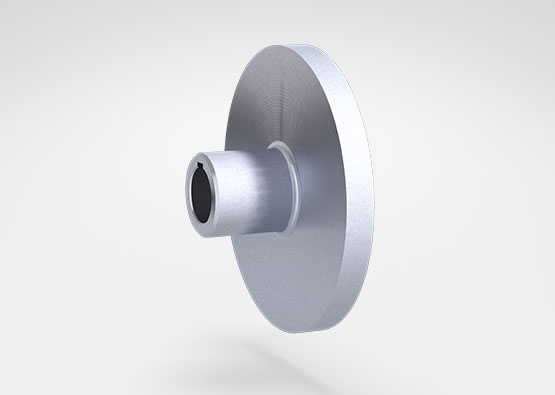

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

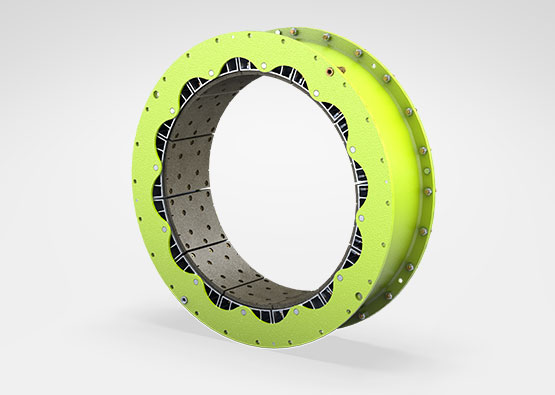

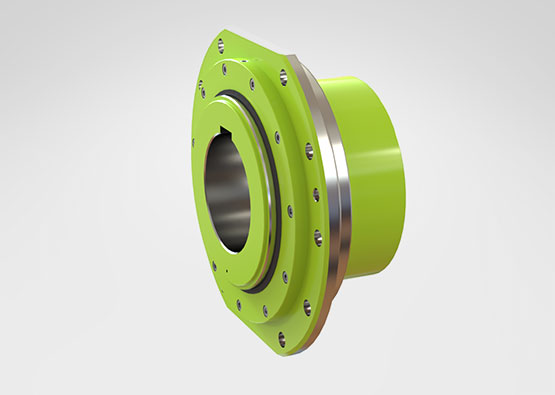

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.

The SB 8 series covers a large part of the versatile industrial applications. It is often used in hoists where installation space is limited and can be equipped with a wide range of options.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyors.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

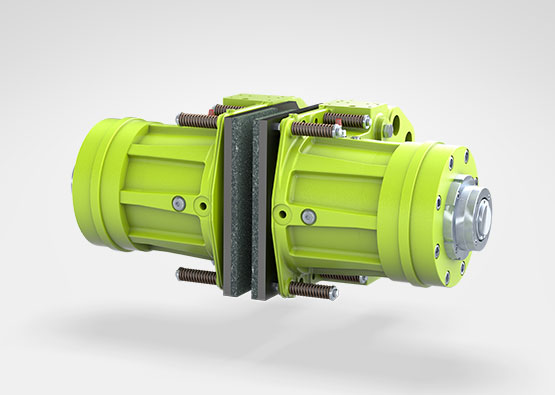

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units. The braking force achieved is directly proportional to the applied pressure.

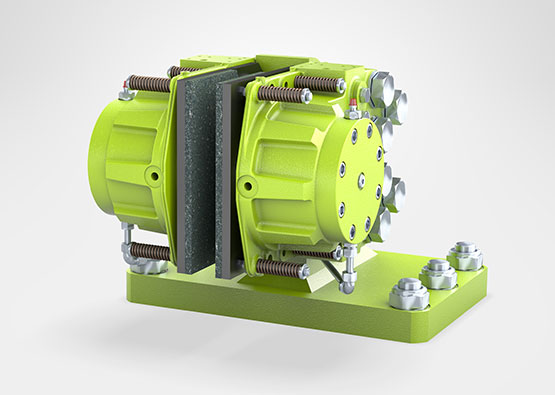

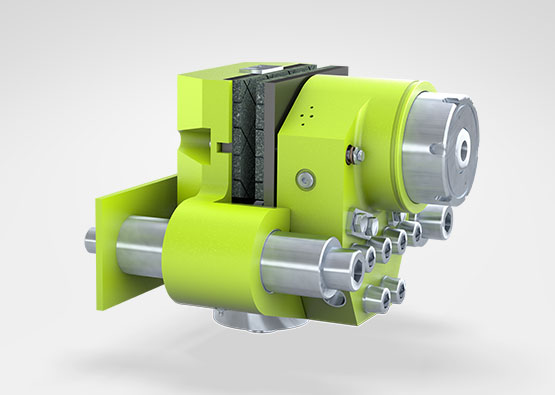

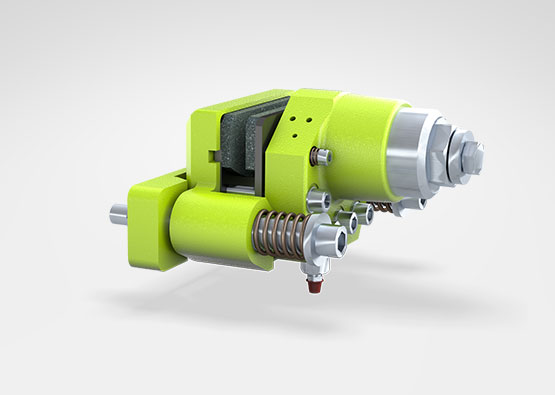

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

Half Wave & Full Wave rectifiers for Din rail or panel mounted rectification.

Gas-hydraulic buffers are installed as impact energy absorber on crane gantries, trolleys, elevators, stackers, reclaimers and other industrial equipment.

Protective element to be connected parallel to the output of the rectifiers BGL, EGL and SGL to increase the interurruption capacity

Din rail mounted unit switches from bridge rectification to half-wave rectification

Iron & Steel