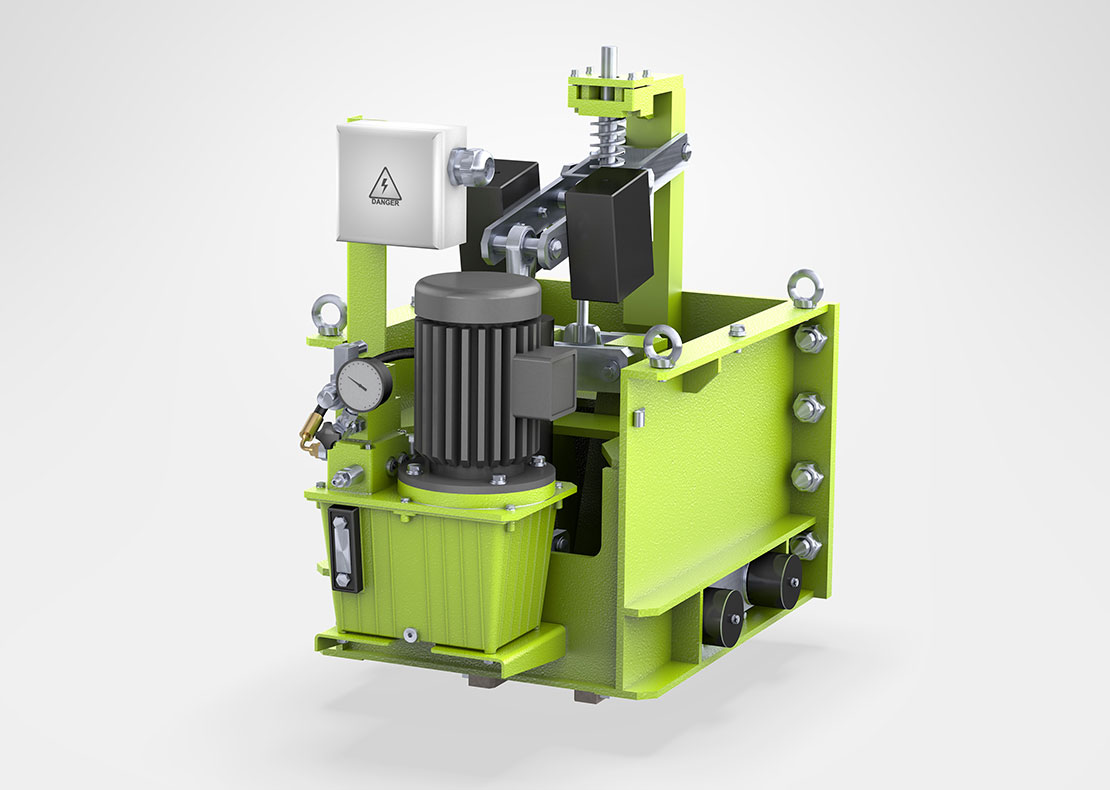

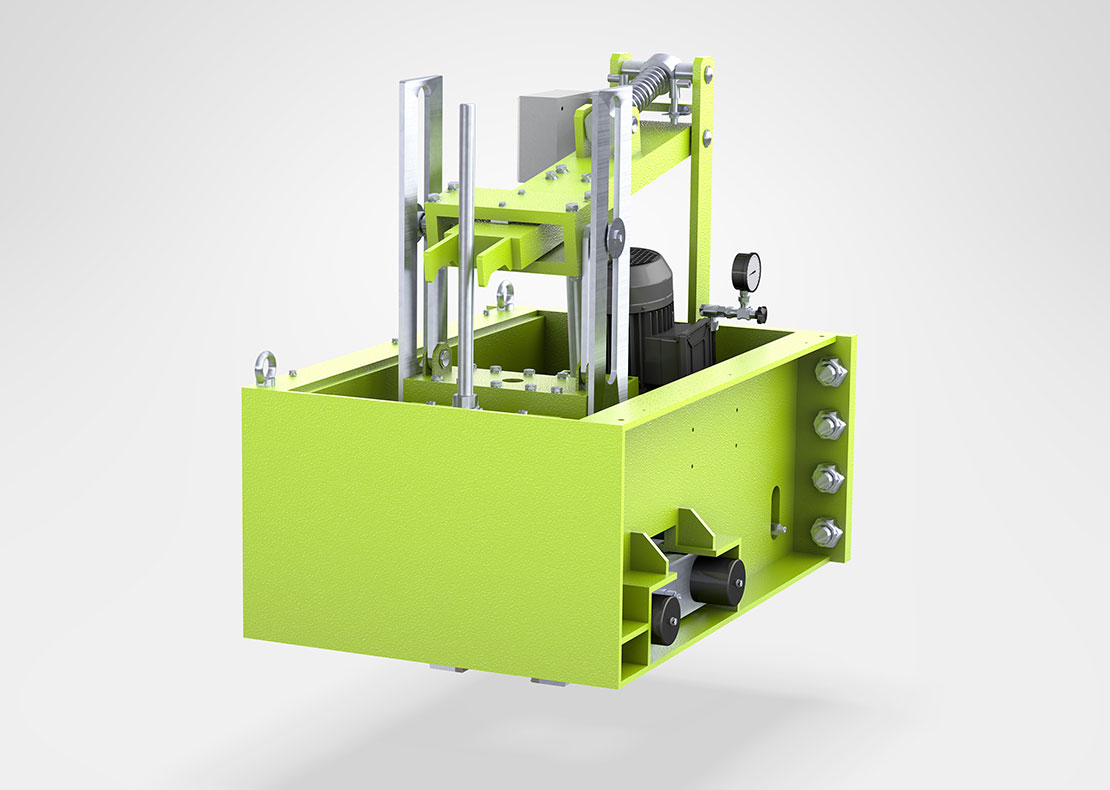

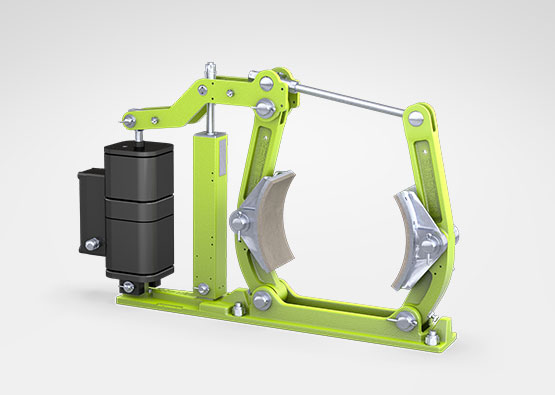

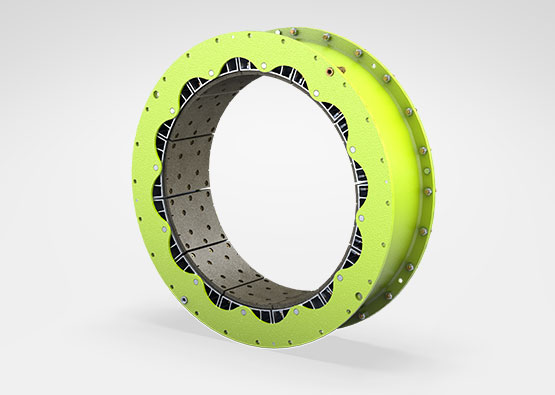

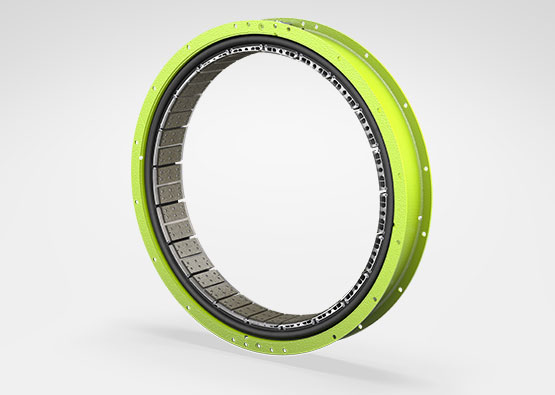

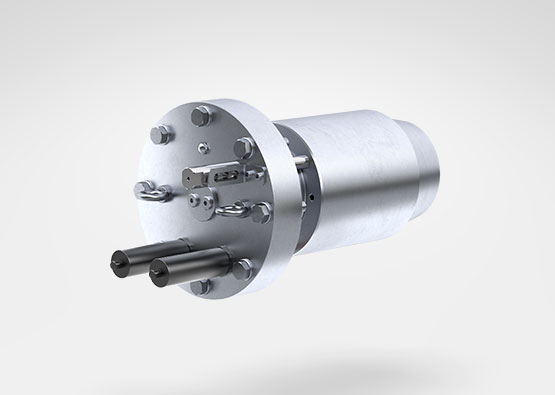

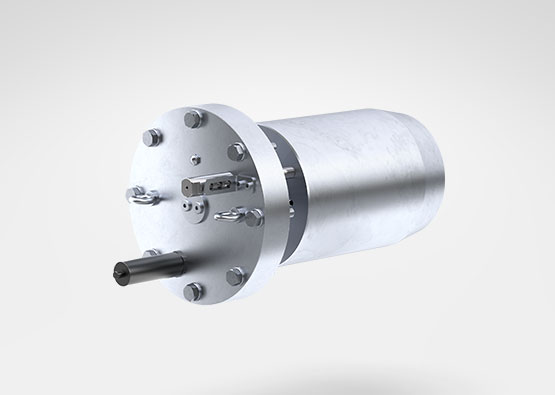

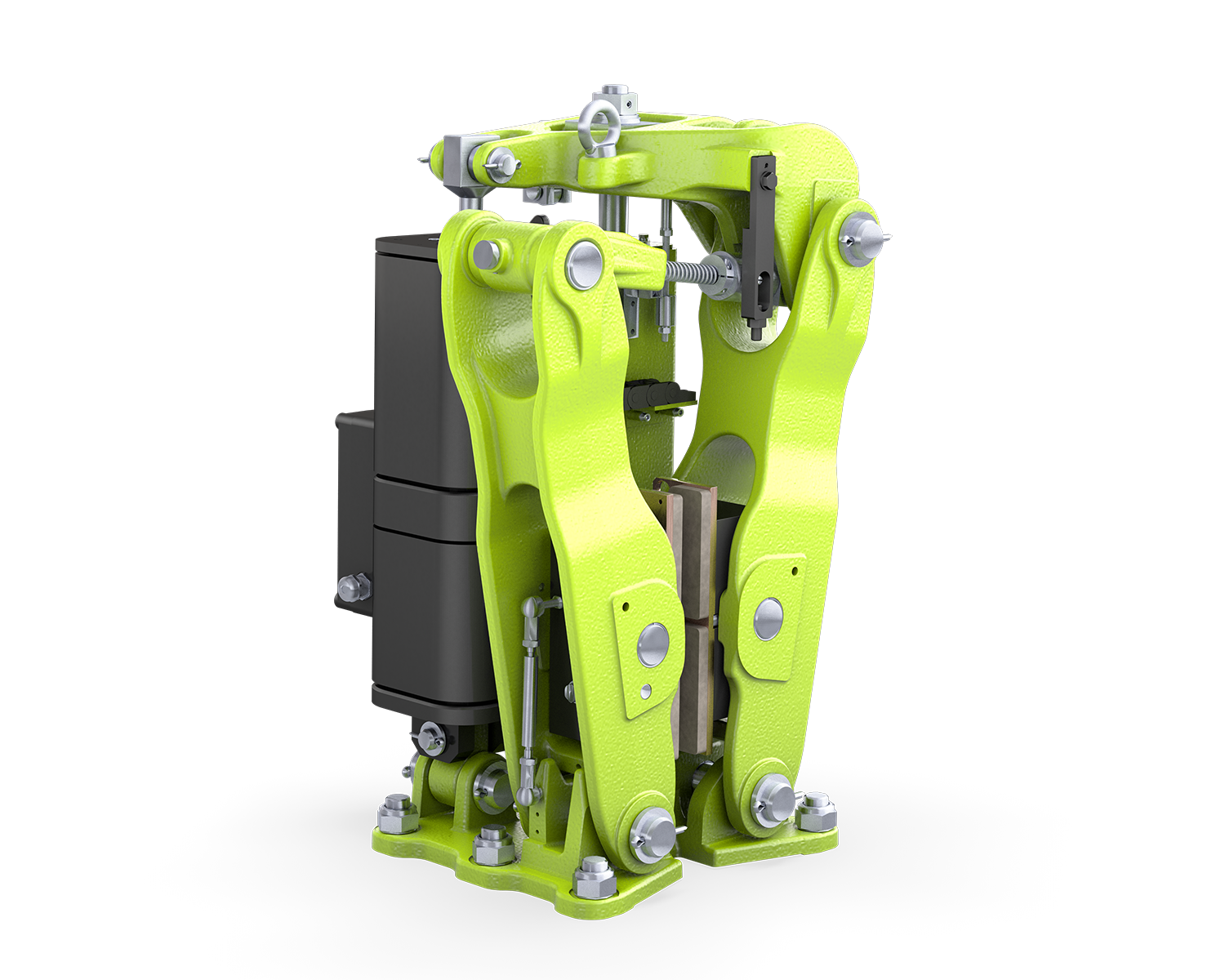

SB 28.5

- Torque:

- 23400 Nm

- Contact Force:

- 65000 N

To uphold our reputation as a global leader in braking systems and manufacturing solutions, the SB 28.5 represents DELLNER BUBENZER’s commitment to constantly innovate, provide industry solutions and anticipate the needs of our customers. Supported by decades of engineering, evolution, and innovation, the SB28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance. Welcome to the SB 28.5, the new generation of SB-disc brake series.

- Proximity switch brake release

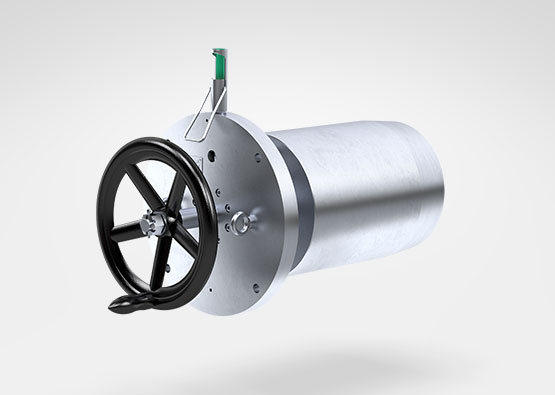

- Manual release lever with or without lock

- Manual release lever latching or non latching

- Automatic wear compensator

- Sintered linings for high friction speeds

- Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube

- Stainless steel pins and spindles

- W-execution (special anti-corrosion protection)

- Maintenance-free bushings in all hinge points

- Symmetric design

- Parallel air gap when brake is released (no tipping of the brake shoes)

- Proximity switch pad wear

- Proximity switch hand release

- Monitoring systems (e.g. VSR/CMB)

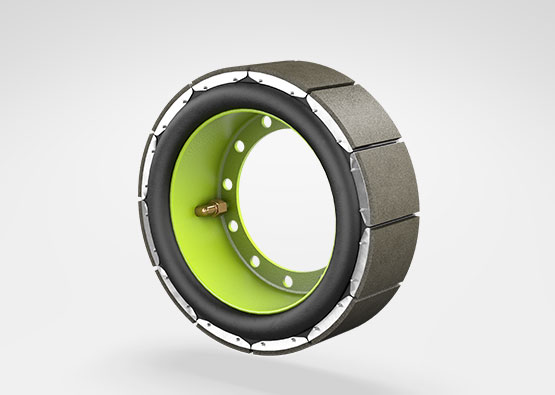

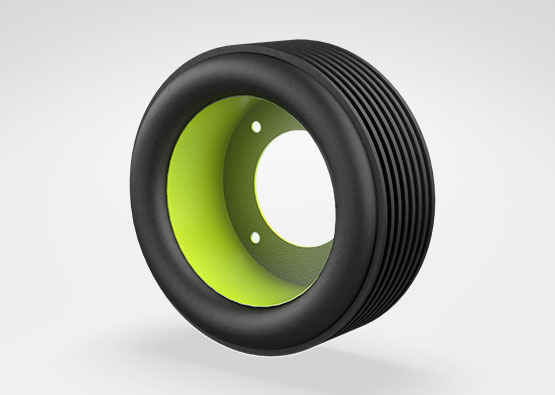

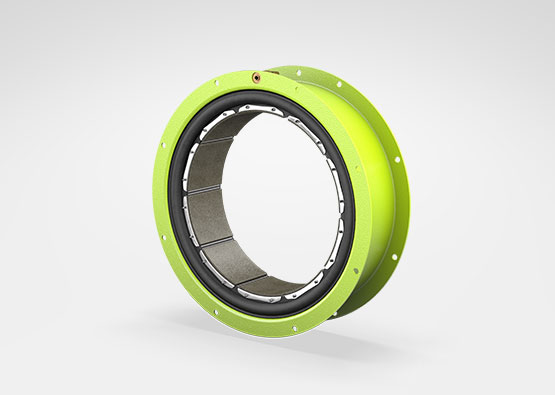

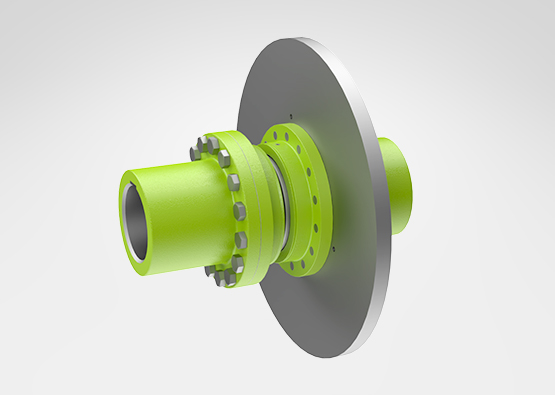

- Brake disc with hub or coupling

- Option: Terminal box for limit switches

- Special painting for increased corrosion protection

- Manual release lever on top of BUEL® thruster

SB 28.5 FEATURES

Sustainability

Developed on the foundation of decades of experience in power transmission, BUEL® sets the industry standard for reliability, safety, and environmental impact.

- BUEL® Thruster & Reduced Energy Costs

- Reduced Fluid Volume

- Eco-friendly Biodegradable Oil

SB 28.5 FEATURES

Enhanced Design

Supported by decades of engineering, the SB 28.5 brake presents significant advantages with preeminent performance and sustainability.

- Facelift, Weight Savings & Reduced Carbon Footprint

- 101 Interchangeability

- Easy Installation & Commissioning

SB 28.5 FEATURES

Automated Wear Compensation

Upgrading our products for optimal performance potential, expands and enhances our product portfolio with precision and expertise.

- Freewheel-based Automatic Wear Compensator

- Easy Maintenance

SB 28.5 FEATURES

Improved Self-Centering System

To uphold our reputation as a global leader, we deploy the latest in technology and mirror what the market needs, and our clients deserve.

- New & Upgraded System by Roller & Cam

- Equal Air Gaps with Self-centering Brake Levers

SB 28.5 FEATURES

Enhanced Parallel Alignment System

- Symmetric Designed Brakes

- Brakes Shoes are Parallel Positioned to the Brake Disc

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

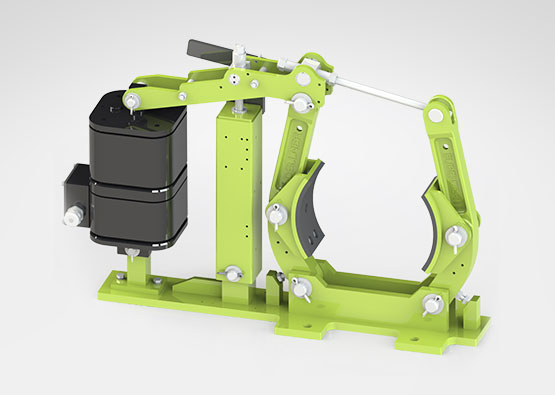

These rail clamps are storm brakes suitable for high forces. They are self-blocking type; in case a force acts on the crane and tends to put the same into motion, they press on the rail sideways.

These rail clamps are storm brakes suitable for high forces. They are self-blocking type; in case a force acts on the crane and tends to put the same into motion, they press on the rail sideways.

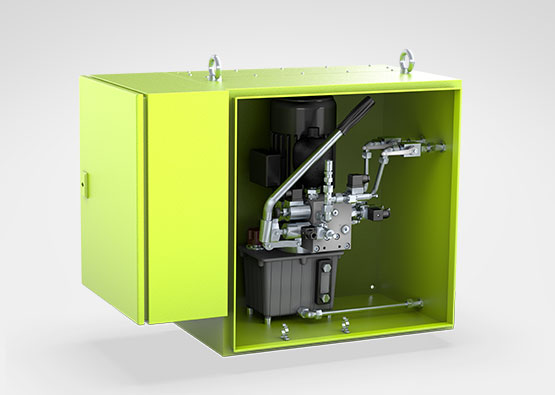

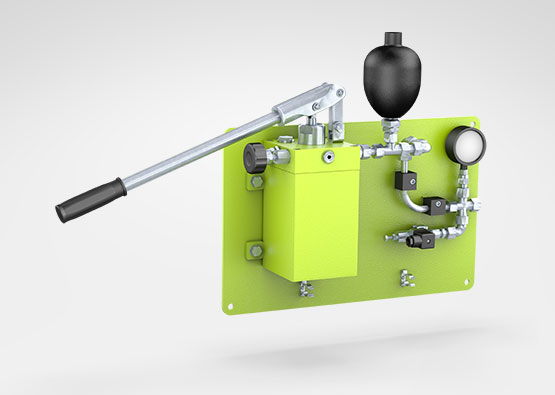

The DH hydraulic power packs deliver pressure up to 200 bar and can be delivered with optional hydraulic cabinets and electrical terminal boxes.

The EBA is a powerful drum brake with braking torques from 24 (ft-lb) to 9000 (ft-lb) that meets AISE (TR11) & NEMA (ICS 8) standards.

The EBH series is designed according to DIN 15435. This design is very compact and can be used in tight motor gearbox combinations.

The EBN series is designed according to DIN 15435 and has been in use in various industries for decades. EBN-2St modification: the drum brakes solution for Bridges and Sluice Systems

The FKE is best suited for applications with light starting and stopping loads. It is also commonly used as a slip clutch or tension brake within light horsepower and torque applications.

The FKR is often referred to as a coupling, as its expanding neoprene rubber facing engages the interior diameter of the drum directly. The resulting friction generates significant torque within a small package.

The FK is well suited as a clutch or brake for a variety of high speed and low to medium torque power transmission applications where high heat generation is not a factor.

The FKT is well suited for applications with the most demanding equipment where severe clutching and braking is required.

The FM is designed and manufactured for marine applications, mainly for use on diesel-driven reduction gears.

Our hand pump can be used to simply activate the Dellner brake calipers. It also acts as a back up system for the primary pressure supply system.

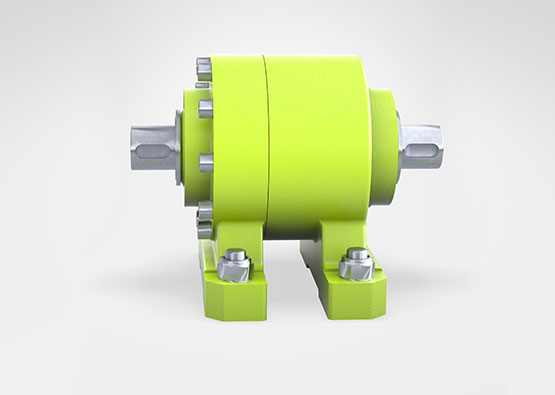

The hydraulic rotary actuator is a device which transform hydraulic power (pressure and flow) in mechanical power: torque and angular speed.

A hydraulic rotor lock offering up to 250 bar pressure with an activation time of 60 seconds.

We offer three models of the JHS-RLH-240 hydraulic rotor lock – the GL Type Certified JHS-RLH-240, the JHS-RLM-240 and the JHS-RLH-240-154. All these locks deliver up to 250 bar pressure with an activation time of just 35 seconds.

Manually activated rotor lock used for safety purposes during maintenance operations to stop the rotor mechanically. The maximum lateral force is 6400 N and the standard stroke is 95 mm. Other strokes are available upon request.

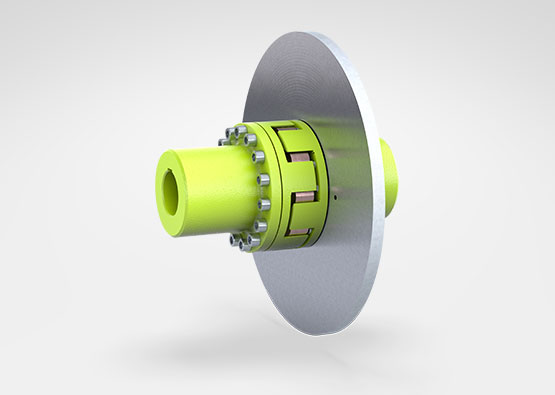

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.