NTRST

- Torsional Force:

- 1390000 Nm

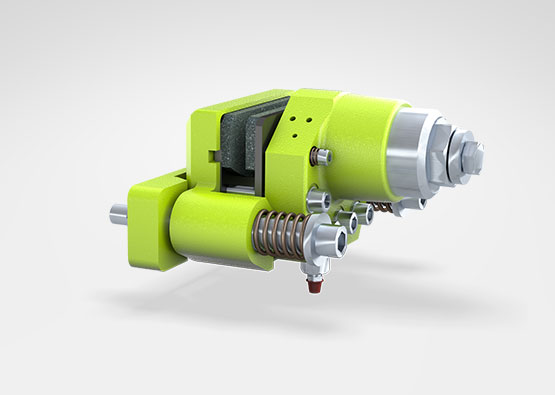

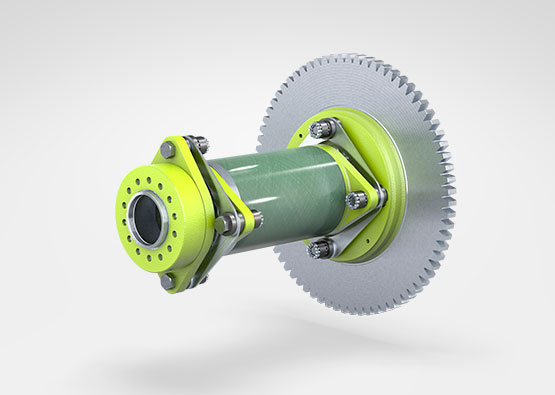

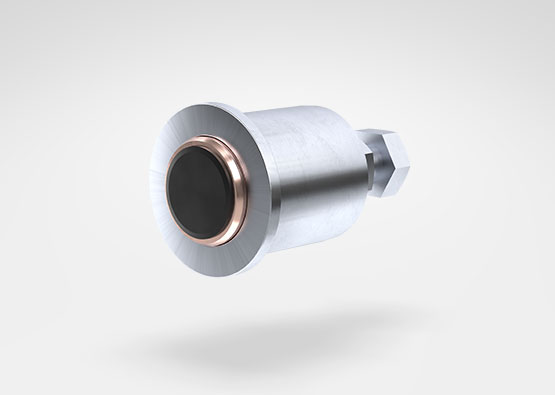

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear. With high torque capacity and durable construction, it delivers exceptional performance in heavy-duty industrial applications. Ideal for cranes, hoists, and conveyors, this drum coupling ensures smooth power transmission with minimal maintenance.

- Barrel coupling made of high-tensile steel

- Torsionally rigid full-steel coupling for transmitting highest torques

- Compentation axial shaft misalignment from +/-3mm up to +/-10mm (depends on coupling size)

- Compensation angular misalignments of +/- 1º

- Simple wear indication

- Acc. to operation sheet of German Steel Iron Industry SEB 666 212

- Drum Coupling with pilot bore

- Coupling with finish bore and one or two keyways

- acc. DIN 6885

- Coupling with finish bore in imperial dimension

- and keyway acc. ANSI B17.1

- Coupling with spline shaft bore

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

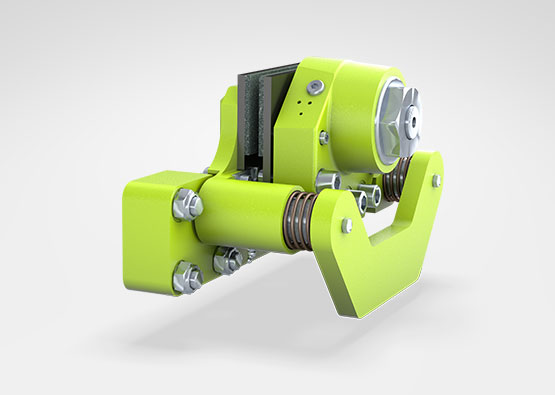

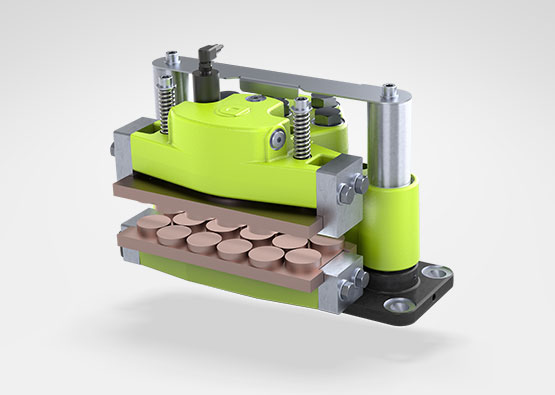

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

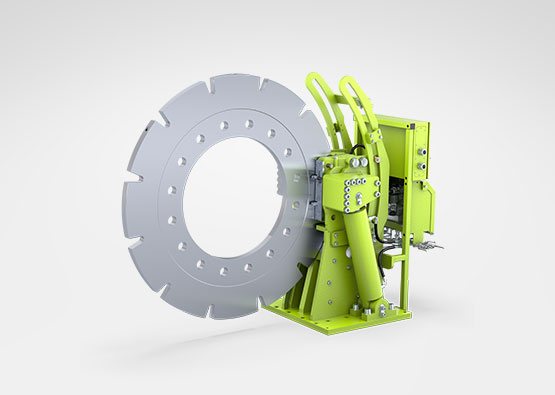

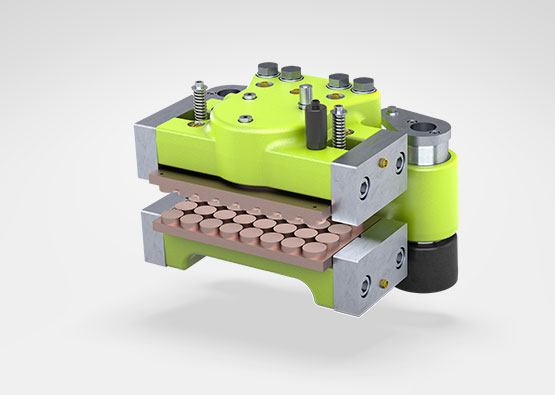

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

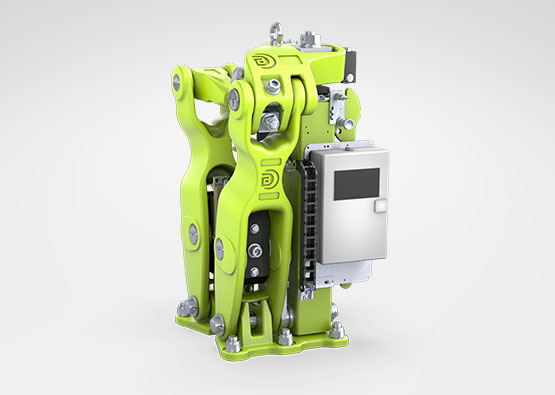

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions.

The Twin Safe is our larger torque twin disc variation of our classic reliable SFB series, used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

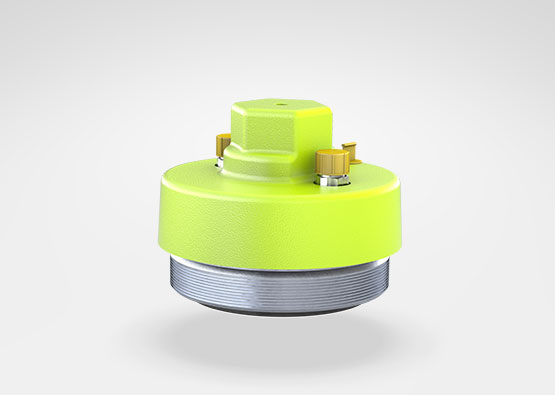

A retrofitable, compact electronic status indication system to be integrated into the brake as an additional device.

A hydraulic active rotor brake with a braking force of 44 kN that’s been specially developed for use in damp, dusty and corrosive working environments

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

JHS WTC is a flexible disc coupling mounted between gearbox and generator. It's a tailor-made solution for wind turbine applications (Type WTC = Wind Turbine Coupling).

A hydraulic active yaw brake with GL Type Certification and braking force of 620 kN.

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.

Half Wave & Full Wave rectifiers for Din rail or panel mounted rectification.