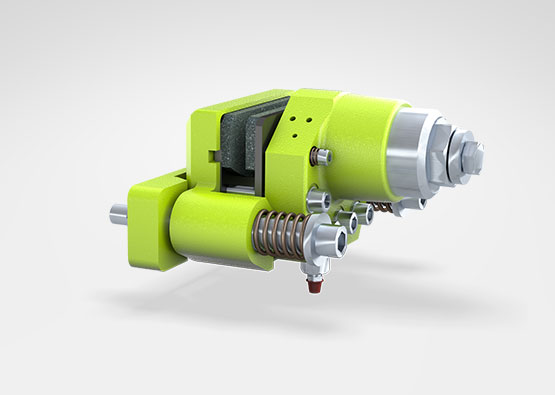

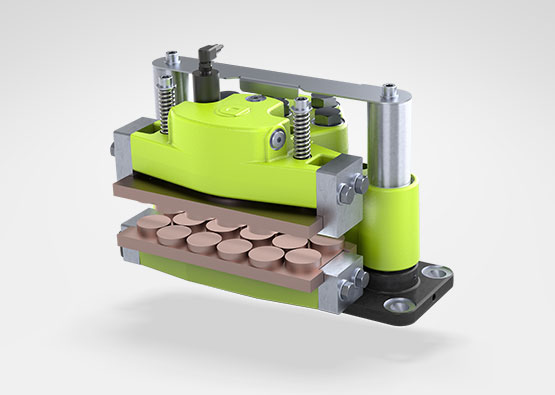

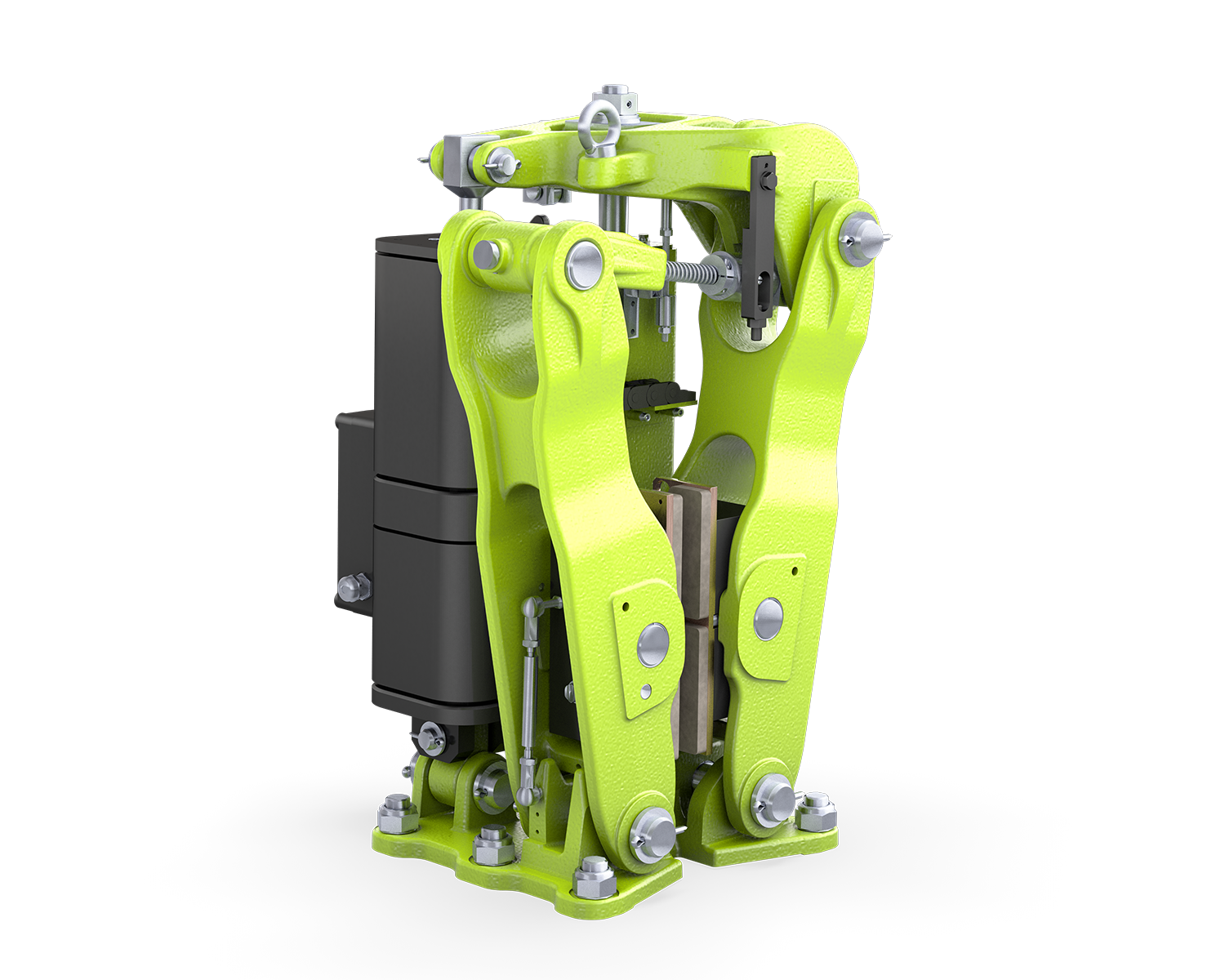

SB 28.5

- Torque:

- 23400 Nm

- Contact Force:

- 65000 N

To uphold our reputation as a global leader in braking systems and manufacturing solutions, the SB 28.5 represents DELLNER BUBENZER’s commitment to constantly innovate, provide industry solutions and anticipate the needs of our customers. Supported by decades of engineering, evolution, and innovation, the SB28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance. Welcome to the SB 28.5, the new generation of SB-disc brake series.

- Proximity switch brake release

- Manual release lever with or without lock

- Manual release lever latching or non latching

- Automatic wear compensator

- Sintered linings for high friction speeds

- Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube

- Stainless steel pins and spindles

- W-execution (special anti-corrosion protection)

- Maintenance-free bushings in all hinge points

- Symmetric design

- Parallel air gap when brake is released (no tipping of the brake shoes)

- Proximity switch pad wear

- Proximity switch hand release

- Monitoring systems (e.g. VSR/CMB)

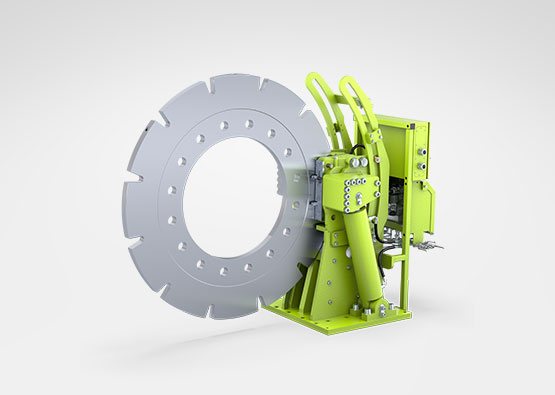

- Brake disc with hub or coupling

- Option: Terminal box for limit switches

- Special painting for increased corrosion protection

- Manual release lever on top of BUEL® thruster

SB 28.5 FEATURES

Sustainability

Developed on the foundation of decades of experience in power transmission, BUEL® sets the industry standard for reliability, safety, and environmental impact.

- BUEL® Thruster & Reduced Energy Costs

- Reduced Fluid Volume

- Eco-friendly Biodegradable Oil

SB 28.5 FEATURES

Enhanced Design

Supported by decades of engineering, the SB 28.5 brake presents significant advantages with preeminent performance and sustainability.

- Facelift, Weight Savings & Reduced Carbon Footprint

- 101 Interchangeability

- Easy Installation & Commissioning

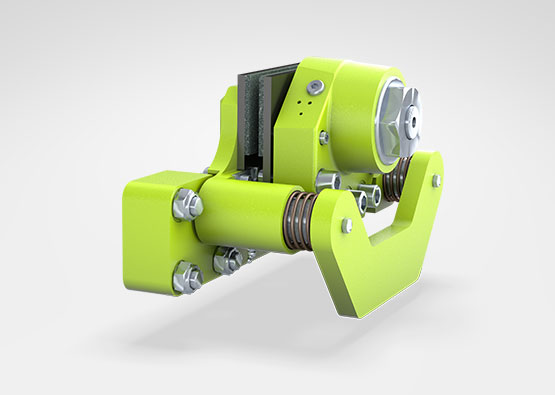

SB 28.5 FEATURES

Automated Wear Compensation

Upgrading our products for optimal performance potential, expands and enhances our product portfolio with precision and expertise.

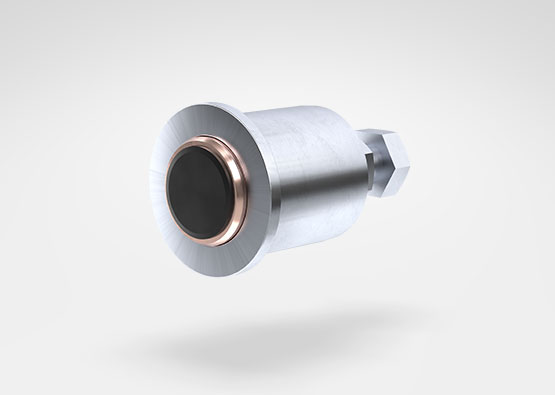

- Freewheel-based Automatic Wear Compensator

- Easy Maintenance

SB 28.5 FEATURES

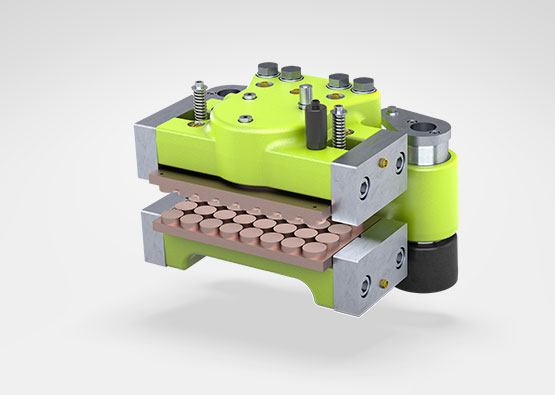

Improved Self-Centering System

To uphold our reputation as a global leader, we deploy the latest in technology and mirror what the market needs, and our clients deserve.

- New & Upgraded System by Roller & Cam

- Equal Air Gaps with Self-centering Brake Levers

SB 28.5 FEATURES

Enhanced Parallel Alignment System

- Symmetric Designed Brakes

- Brakes Shoes are Parallel Positioned to the Brake Disc

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

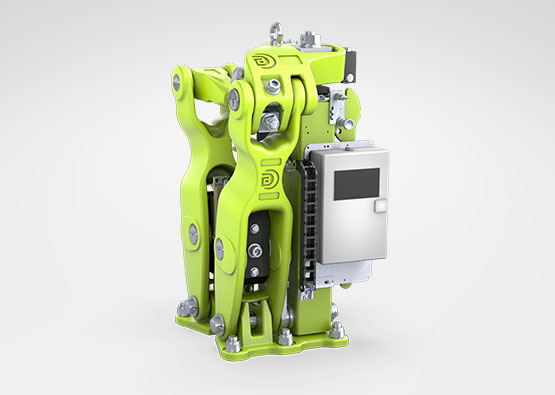

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions.

The Twin Safe is our larger torque twin disc variation of our classic reliable SFB series, used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

A retrofitable, compact electronic status indication system to be integrated into the brake as an additional device.

A hydraulic active rotor brake with a braking force of 44 kN that’s been specially developed for use in damp, dusty and corrosive working environments

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

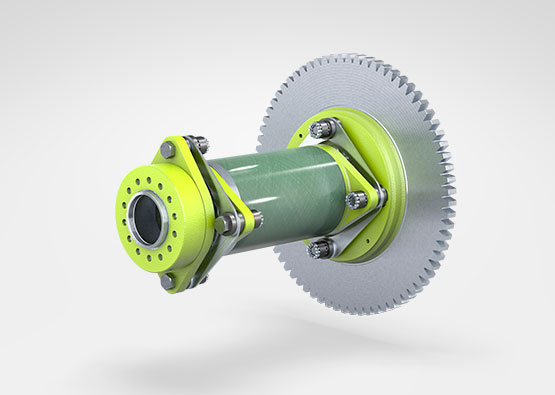

JHS WTC is a flexible disc coupling mounted between gearbox and generator. It's a tailor-made solution for wind turbine applications (Type WTC = Wind Turbine Coupling).

A hydraulic active yaw brake with GL Type Certification and braking force of 620 kN.

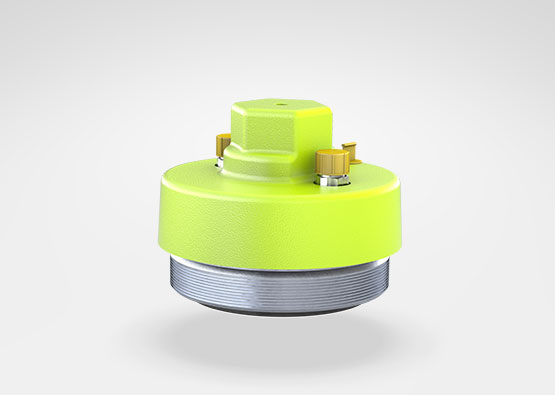

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.